Our approach to manufacturing emphasizes our core values

of quality, innovation and vertical integration.

PSI can stamp product ranging from .001″ (.0254mm) to .060″ (1.524mm) thick in the following alloys: Phosphor Bronze, Beryllium Copper, Copper, Nickel-Silver, Stainless Steel, Brass, and a wide range of other alloys.

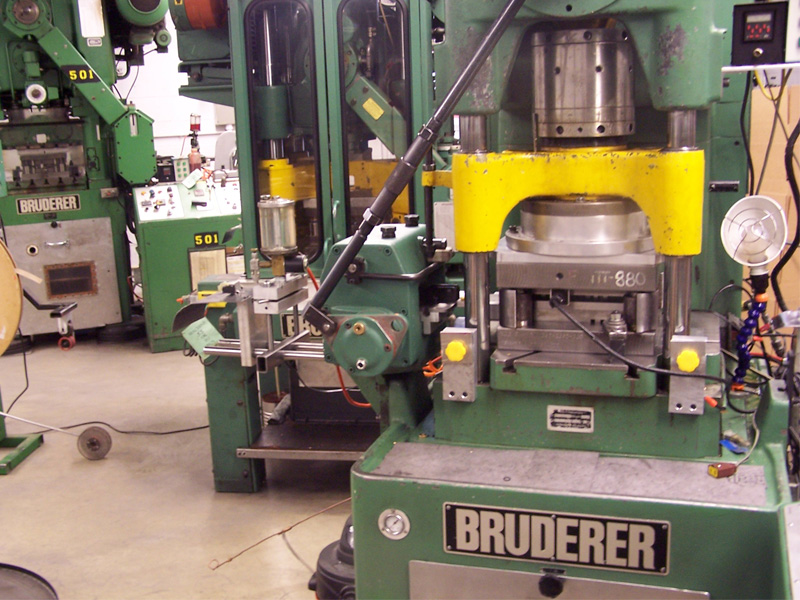

Our equipment list features more than 30 Bruderer presses. Complementing them are presses by Minster, Rousselle, Diemaster, Walsh and Rockford. This diversity of equipment ensures we will always have the perfect press for your particular application. The capabilities of our presses, coupled with the continuous improvements by our Design and Tooling groups, ensure consistent quality, competitive pricing and shorter lead times.

All required die maintenance is provided by PSI throughout

the life of your product at no charge. Our Tool Protection System, which integrates preventative maintenance with the most advanced sensor technology available safeguards all dies in our custody. If an interruption occurs, our system also points to the source of the problem, speeding up the troubleshooting process and eliminating costly down time.

Every aspect of the manufacturing process is continually reviewed and upgrades are put in place as soon as they become available. From material payoff, to straighteners, to rewind equipment, to our advanced sensors and optical inspection devices; we take pride in staying ahead of the curve and ahead of our competition.

Our in-house heat treating and plating departments ensure that these vital operations are performed with the same dedication to perfection found in all aspects of Precision Stampings’ manufacturing processes.